Inductively Coupled Plasma (ICP) has been widely used for crystal etching1, semiconductor etching2, thin film deposition3, material surface modification4,5and so on. However, accurate and skilled use of these processes requires a clear understanding of the various ICP control factors such as ICP internal pressure and absorbed power. These control factors can sensitively affect the electron density, electron temperature and other physical parameters of ICP, thus profoundly affect the accuracy of production process. Especially important, the local pressure in a low-pressure plasma affects the mean free path of collisions between electrons and neutral particles, which is closely related to local and non-local dynamic characteristics6, electron heating and heating efficiency, electron energy distribution7and electron density8, discharge mode (E or H mode)9,10and so on. Therefore, the local pressure is a very important external parameter of low-pressure plasma, especially in terms of accuracy control during the plasma process. As an electrical parameter, absorbed power can be accurately measured by tracing its source. However, the local pressure in ICP is difficult to be accurately measured because of the distance between the sensor of the vacuum gauge and the plasma region to be measured. To understand the actual pressure in the plasma, it is necessary to calibrate the local pressure in ICP. This provides quantitative pressure parameters for studying the physicochemical mechanisms of various processes in ICP.

Electron density and electron temperature are the main physical parameters to characterize the plasma, so the high agreement between their finite element simulation results with the experimental results can fully guarantee the reliability of the computational model. Both simulation and experiment reveal that the gradient in the electron density distribution of ICP is very pronounced under H-mode discharge condition. The plasma is firmly bound inside of the coil by the inductor coil. As a statistical physical quantity, the measured or simulated electron temperature has no significant gradient distribution. Obviously, the identification of electron density is much higher than that of electron temperature11,12and there is a close correlation between electron density and electron temperature13. So we can focus on comparing the distribution of electron density to determine whether the external conditions of the simulations and experiments in this paper are consistent. However, this comparison depends on accurate and reliable measurements of electron density. At present, the commonly used measurement methods for ICP electron density include Langmuir probe method14, emission spectroscopy15, microwave interferometry16, laser interferometry17and laser Thomson scattering (TS) measurement18. Among these techniques for measuring plasma electron density, the TS can measure the electron density in a given region without disturbing the plasma, and has very high spatial and temporal resolution19. It is recognized as one of the most accurate electron density measurements available. So in this paper we use TS to measure the electron density distribution of ICP.

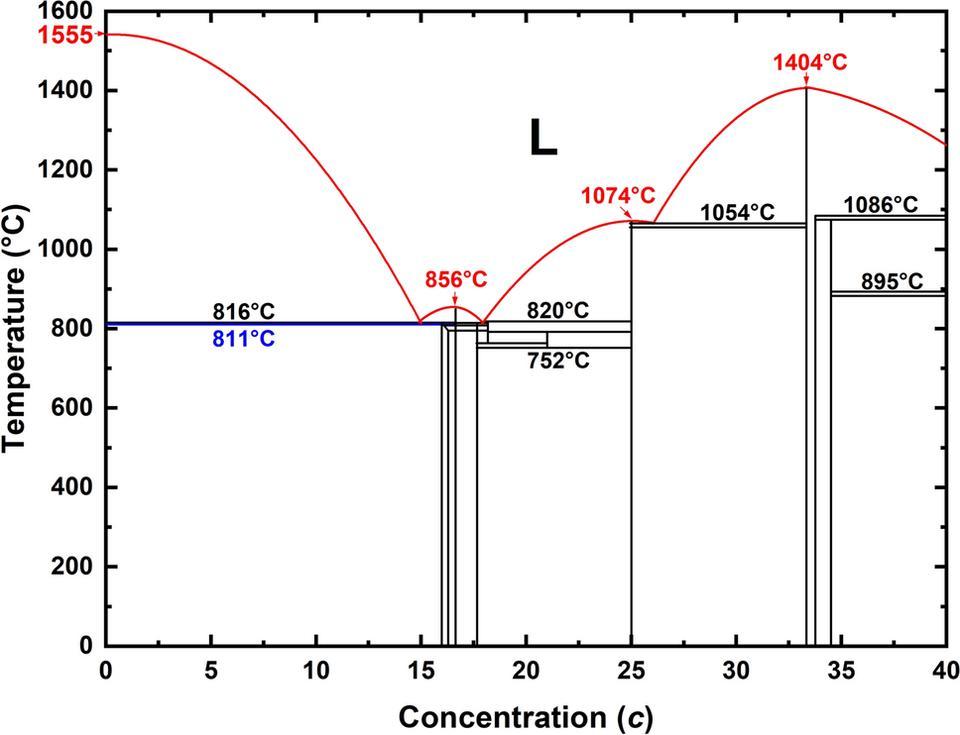

Accurate measurement and calibration of pressure, especially local pressure, has rarely been reported in previous research work. In 2007, Shimada20measured the spatial distribution of neutral gas temperature and total pressure, electron pressure and neutral pressure by inserting a thin tube probe with diameter of 3.15 mm into the plasma. However, this interventional measurement itself interferes with the local environment of the measurement area, making it difficult to achieve accurate measurements. In order to avoid the measurement uncertainty caused by interventional measurements, a new method of ICP local pressure calibration combining TS experiments and finite element method (FEM) simulations is proposed in this paper. First, the electron density distribution of ICP is measured non-invasively by laser TS. The ICP pressure to be calibrated is measured by a vacuum gauge probe (TPG 201, Pfeiffer Vacuum) at the gas inlet of the ICP generator. The absorbed power of the ICP is the product of the input power of a 13.56 MHz RF power supply and the power transfer efficiency. As the power and pressure change, the plasma density changes, and the plasma load on the matching network varies accordingly. To compare the experimental and simulated values of electron density distribution at a specific absorbed power, the capacitance in the matching circuit is experimentally adjusted by Smith chart to match the internal impedance of the RF power supply so that a given power such as 400 W, 350 W and 300 W is transmitted into the plasma. The power transfer efficiency is 96.3%, 94.9% and 93.0% at an absorbed power of 400 W, 350 W and 300 W, respectively, as measured by a similar method in reference21. Second, a FEM model with the same physical dimensions as the ICP generator experimental setup is established. At the same absorbed power as the experiment, the pressure measured by the vacuum gauge is taken as the reference starting point, and the pressure is scanned in the lower pressure direction. The resulting simulation yields a series of spatial distributions of the electron density with pressure in the ICP generator cavity. Third, this series of plasma electron density simulation data is used as the true value of the measurement and compared with the electron density data measured by TS. When both the experimental and simulated electron density distributions and maxima are within the error tolerance, the pressure value in the simulation can be determined as the corrected value for the pressure measurement. This completes a single pressure data calibration of the ICP generator. This cycle can be repeated to complete a pressure calibration simulation curve for a specific ionized gas at a given absorbed power. At last, combined with the theoretical model, the equation coefficients associated with the ICP generator experimental system are obtained by fitting the pressure calibration simulation curve using the least square method, so as to obtain the theoretical pressure calibration curves for the different absorbed powers. Both simulated and theoretical calibration curves can be used for the local pressure calibration in low-pressure plasma processes.